Rolling Mill Machinery

(1014 products)Automatic Cr Reversible Rolling Mill

5000000 INR (Approx.)/Piece

MOQ01 Piece/Pieces

TypeCold Rolling Mill

MaterialMild Steel

Automatic GradeAutomatic

Semi-Automatic Spindle Coupling/Cross Joint

Price Trend: 500.00 - 1500.00 INR/Unit

MOQ50 Unit/Units

TypeSpindle Coupling/Cross Joint, Other

MaterialMild Steel

ComputerizedNo

Automatic GradeSemi-Automatic

Control SystemFrequency Speed Control

WarrantyYes

Ugi Engineering Works Pvt. Limited

Kolkata

Double Pinch Plate Roling Machine

Product DescriptionWe are among the distinguished names in the industry, engaged in Exporter, Manufacturer & Supplier of Double Pinch Plate Roling Machine. The design reduces to a minimum the distance between the bending points guaranteeing maximum bending accuracy.\015\012The bearing system, incorporating 4 freely be

Berlin Machineries Private Limited

Pune

Trusted Seller

Trusted Seller5 Years

Automatic Three Roll Mill Machine

Price: 350000 INR/Unit

MOQ1 , Unit/Units

TypeOther, Three Roll Mill Machine

MaterialMild Steel, Stainless Steel

Automatic GradeAutomatic

Pratham Engineering

Mira Bhayandar

Trusted Seller

Trusted Seller14 Years

Automatic Cr Reversible Rolling Mill

Price: 5000000 INR/Piece

MOQ01 Piece/Pieces

TypeCold Rolling Mill

MaterialMild Steel

Automatic GradeAutomatic

Hertz Controls (india) Private Limited

Ghaziabad

Shaftless Mill Roll Stand - 2200 mm Width, Max Roll Diameter 1500 mm | Hydraulic Lifting, Electric Control, Pneumatic Disk Brake, Motorized Clamping

Product DescriptionOwing to our proficiency in this domain, we offer our clients a wide gamut of Shaftless Mill Roll Stand\015\012\015\012\357\203\230\011Main Structure and Features\015\012\342\200\242\011Hydraulic paper roll lifting and lowering \015\012\342\200\242\011Electric control cabinet and operation box are

Senior Paper Packing Machinery Mfg. Co.

Amritsar

Temper Rolling Mill - Automatic Grade: Semi-Automatic

Price: 100000.0 USD ($)/Unit

MOQ1 Unit/Units

TypeCold Rolling Mill

MaterialCustomized

Capacity5000 Ton

ComputerizedYes

Automatic GradeAutomatic

Control SystemPLC Control

Beijing Ywlx Sci & Tech Co., Ltd

Beijing

Premium Seller

Premium Seller1 Years

Hot Rolling Mill - High-Strength, Robust Design | Efficient Metal Deformation, Enhanced Heat Resistance

TypeOther, Rolling Mill

MaterialSteel

Capacity500 Tons Per Day

ComputerizedYes

Automatic GradeAutomatic

Control SystemOther, PLC

Rolltech Engineering Pvt. Ltd.

Sabarkantha

Ball Mill GMP Model

Product DescriptionOur hi-tech infrastructure is equipped with latest technology machinery which help us in offering the best range of Ball Mill CGMP models. These range are made by using best quality raw materials which have been sourced from the trusted vendors of the industry to maintain the quality and reliability

Industrial Rolling Mill Machine - Automatic Grade: Semi-Automatic

Price: 100000 INR/Unit

MOQ10 Unit/Units

MaterialStainless Steel

ComputerizedNo

Automatic GradeSemi-Automatic

Control SystemFrequency Speed Control

Kalpatech Engineers And Industries Limited

Nashik

Sheet Rolling Machine - High-Quality Steel Fabrication, Industrial Durability and Precision Engineering

Product DescriptionOur experience lies in manufacturing and supplying an exceptional range of Sheet Rolling Machine to our valuable clients. Overall range is manufactured by our talented pros in complying with the set industrial quality standards. Moreover, these machines is firmly tested on various factors of quality

Automatic Cold Rolling Mill Machinery

Price: 1000000.00 INR/Piece

MOQ1 Piece/Pieces

TypeCold Rolling Mill

MaterialStainless Steel

Automatic GradeAutomatic

Triple Roller Machine - High-Quality Steel Finish | Easy Installation, Rust Proof Coating, Leak Proof Design

Price: 330000 INR/Unit

MOQ1 Unit/Units

TypeOther, Triple Roll Mill

MaterialMS

Automatic GradeAutomatic

Warranty12 Months

Cement Raw Mill - Premium Quality Material , Expertly Crafted for High Performance and Durability

Product DescriptionWe are supported by a team of industry\342\200\231s best professionals who are highly experienced and made these Cement Raw Mill with extreme perfection. These range are made by using best quality raw materials which have been obtain from the trusted vendors of the industry. Keeping in mind the budg

Mill Rolls For Food and Feed Industry

Product DescriptionWe are interested in manufacturing, trading and supplying a wide range of Mill Rolls For Food and Feed Industry in Malerkotla, Punjab, India. India factory manufactures mill rolls for cereal & grain milling, oil seed crushing, flour & feed milling, rice flaking, biscuit, coffee & chocolate industrie

India Factory

Malerkotla

Trusted Seller

Trusted Seller16 Years

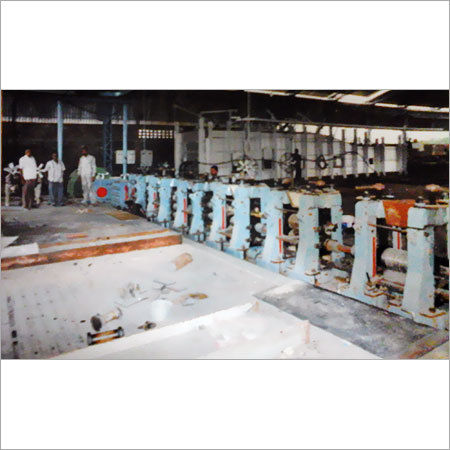

Steel Rolling Mill - High-Quality Raw Material, Customized Specifications for Versatile Applications

Product DescriptionOwing to the advanced manufacturing technology in our fully developed infrastructure, we are capable in offering our clients an extensive variety of Steel Rolling Mill . Our products are manufactured using quality raw material which comply to all set standards and norms of the industry

User Friendly Plate Rolling Machine

MOQ1 Number

Product DescriptionOur company is engaged in manufacturing and supplying a high quality array of Plate Rolling Machine. These machines are engineered from finest quality components and advanced technology in compliance with the defined industry standard. This is appreciated among the clients for optimum quality and hi

Automatic Precision Wire Rolling Mill Production Line

Price: 6000 INR/Set

MOQ1 Set/Sets

TypeCold Rolling Mill

Materialrolling from round wires into flat&shaped ss wire,carbon steel wire,alloy wire

ComputerizedYes

Automatic GradeAutomatic

Control SystemPLC Control

Sky Bluer Environmental Technology Co Ltd

Zhangjiagang

Wedge Rolling Mill - Max. Machining Diameter 32 mm, Roll Gap Adjustment 15 mm | Automatic PLC Control, Metal Material, Compact Size

MOQ1 Unit/Units

TypeOther, Wedge Rolling Mill

MaterialMetal

ComputerizedNo

Automatic GradeAutomatic

Control SystemPLC Control

Zibo Hongjie Forging Industry Equipment Co, Ltd

Zibo

Plate Rolling Machine 60 Mm - Automatic Grade: Automatic

Price: 4900000 INR/Piece

MOQ1 Piece/Pieces

TypeOther, Plate Rolling Machine 60 mm

MaterialMild Steel

Capacity20 Ton/day

ComputerizedNo

Automatic GradeAutomatic

Voltage220-440 Volt (v)

Victory Machinery Corporation

Mumbai

Iron Roller Crusher

Price: 500000 INR/Piece

MOQ1 Piece/Pieces

Supply Ability10 Per Week

Delivery Time1 Days

Kameyo Systems Private Limited

Greater Noida

Jewelry Rolling Mills

Product DescriptionWe deal in a comprehensive range of Rolling Mills which find wide utilization in different jewelery making firms. These mills, available in different specifications, are convenient to install due to their compact design. They are anti corrosive in nature and ideal for handling bulk production.\015\

Industrial Plate Rolling Machine - Automatic Grade: Semi-Automatic

Price: 425000 INR/Unit

MOQ1 Unit/Units

MaterialMild Steel

Capacity5 Ton/day

Automatic GradeSemi-Automatic

Control SystemHuman Machine Interface

Voltage280 Volt (v)

Power7.5 Horsepower (HP)

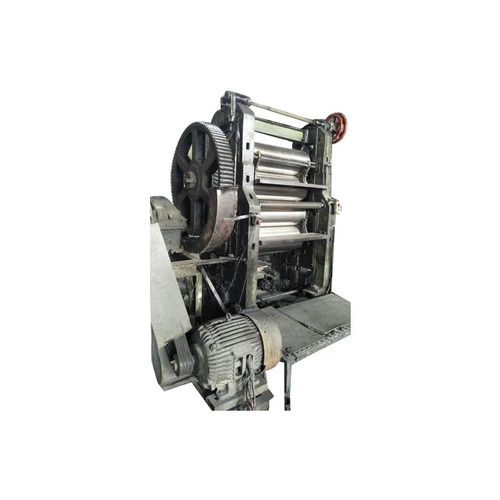

Three Roll Mill Machine

Sample AvailableYes

Sample PolicyContact us for information regarding our sample policy

Main Export Market(s)Asia

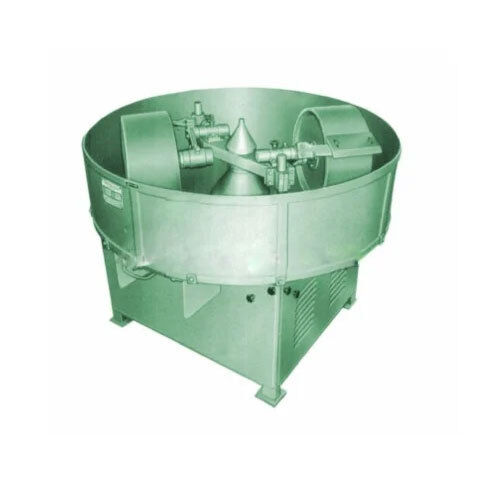

Sand Mixer Muller - Aluminium Silicon Material , Semi-Automatic Operation, 1-Year Warranty

MOQ1 Piece/Pieces

TypeOther, Sand Mixer Muller

Materialaluminium silicon

ComputerizedNo

Automatic GradeSemi-Automatic

Warranty1 Year

Metal Automatic Rolling Mill Machine

Price: 750000 INR/Unit

MOQ1 Unit/Units

TypeCold Rolling Mill

MaterialMetal

ComputerizedNo

Automatic GradeAutomatic

Control SystemHuman Machine Interface

WarrantyYes

Hydraulic Rolling Machine - Automatic Grade: Semi-Automatic

Price: 500000 INR/Unit

MOQ1 Unit/Units

TypeOther, Hydraulic Rolling Machine

MaterialStainless Steel

Capacity20 Ton

Automatic GradeSemi-Automatic

Voltage440 Volt (v)

WarrantyYes

Rolling Mill Fly Wheels

Product DescriptionA Rolling Mill Fly Wheels is heavy metal Rolling Mill Fly Wheels attached to a drive shaft, having most of its weight concentrated at the circumference. Main function of flywheel is to reduce speed fluctuation by storing extra energy during part load as kinetic energy and same is released during ove

S M T Machines (india) Limited

Mandi Gobindgarh

Expanded Metal Machine - Automatic Grade: Semi-Automatic

Price: 550000 INR/Unit

MOQ1 Piece/Pieces

MaterialSS

ComputerizedNo

Automatic GradeSemi-Automatic

Control SystemHuman Machine Interface

Voltage220-240 Volt (v)

Warranty1 Year

Shree Jagdamba Enterprises

Delhi

Premium Seller

Premium Seller9 Years

Latest From Rolling Mill Machinery

High Precision 2 Hi Rolling Mill

By:

Sky Bluer Environmental Technology Co Ltd

Heavy Rolling Mill Machinery

By:

Shree Tech

TAJ Rolling Mill Machinery

By:

Taj Foundary & Engg. Works

Hot Rolling Mill Machinery

By:

T. K. Mondal & Co.

Rolling Mill Machine

By:

Acier Equipment

Hot Rolling Mill Plant

By:

Mahashakti Engineering Works

Hot Rolling Mill Machine

By:

A. R. Engineering Works

Ready To Ship Rolling Mill Machinery

What is rolling mill machinery?

Working principle of rolling mill machinery

1. Roll Bending

2. Flat Rolling

3. Ring Rolling

4. Controlled Rolling

5. Forge Rolling

Types of Rolling Mill Machinery

1. Planetary Rolling Mill machinery

2. Continuous Mill Machinery

3. Cluster Rolling Mill Machinery

4. Four-high Rolling mill machinery

5. Three high Rolling Mills

Uses & benefits of rolling mill machinery

There are many benefits to using a rolling mill, and they apply equally to both large and small firms.

1. Perfect for Metalworking

2. Generally Reliable

3. Conveniently Simple to Operate

4. Superior Productivity Rate

5. Spend less on maintenance and operations.

Conclusion

FAQ's: Rolling Mill Machinery

Q. What are the types of rolling mill Machines?

Q. How does a rolling mill machine work?

Q. What is the cost of rolling mill machine?

Manufacturers & Suppliers of Rolling Mill Machinery

Company Name | Member Since |

|---|---|

Ugi Engineering Works Pvt. Limited Kolkata, India | 22 Years |

Vaid Engineering Industries Delhi, India | 21 Years |

S M T Machines (India) Limited Mandi Gobindgarh, India | 21 Years |

Senior Paper Packing Machinery Mfg. Co. Amritsar, India | 20 Years |

Micro Pulverizer Mfg Works Mumbai, India | 17 Years |

India Factory Malerkotla, India | 16 Years |

Pratham Engineering Mira Bhayandar, India | 14 Years |

Creative Carbon Pvt. Ltd. Ahmedabad, India | 13 Years |

Nilkamal Industries Rajkot, India | 13 Years |

Kameyo Systems Private Limited Greater Noida, India | 12 Years |

Popular Products