Sectional Warper - Nom

Price:

Get Latest Price

In Stock

Product Specifications

| Working Width | 2200/3600 Mm |

| Warping Beam Diameter | 800 Mm |

| Warping Speed | 1000 M/Min |

| Beaming Speed | 200 M/Min |

| Sizing Separations | 7 Lease |

| Creels | Parallel |

| Control System | Dnc Kamcos |

| Features | Fast Warping High Quality Automatic Leasing Compact Design Laser Control Easy Operation Efficient Production Reduced Handling Improved Yarn Use Shorter Setup |

| Payment Terms | Cash on Delivery (COD) Cash Against Delivery (CAD) Cash Advance (CA) Cash in Advance (CID) |

| Delivery Time | 15-20 Days |

| Sample Policy | Within a certain price range free samples are available |

| Main Domestic Market | Delhi |

Product Overview

Key Features

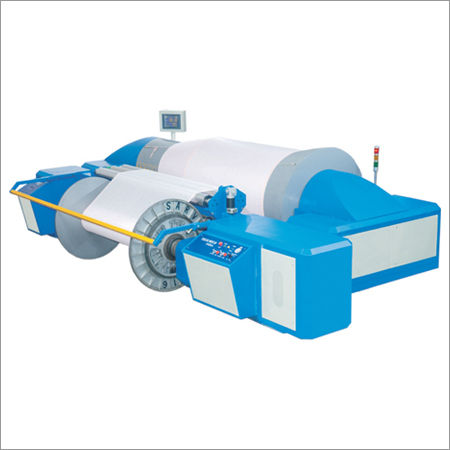

New Dimension in sectional Warping -The economic alternative to the production of quality short warp

Technical Details:

Working width: 2200 and 3600 mm

Warping beam diameter: 800 mm

Warping speed up to 1000 m/min

Beaming speed up to 200 m/min

Sizing separations: 7 lease

Parallel creels with appropriate yarn tensioner for all type of yarn

Parallel creel execution with wagon swivel magazine and fixed type

Option of waxing and press roll device

Control DNC KAMCOS

Applications:

Shirting worsted silk bottom weights home textiles and apparels

Key Features:

Smaller warping drum - 600 mm diameter (instead of 1.000 mm) for faster positioning / breaking

Automatic leasing and section-change over - reliable leasing plate instead of shaft leasing device with healds

Genuine leasing cord automatically inserted - reduced manual handling before beaming operation

Shed opener and i? control - for secure and fast leasing

Compact beaming device for easier operation - ergonomic design with simple effective operations

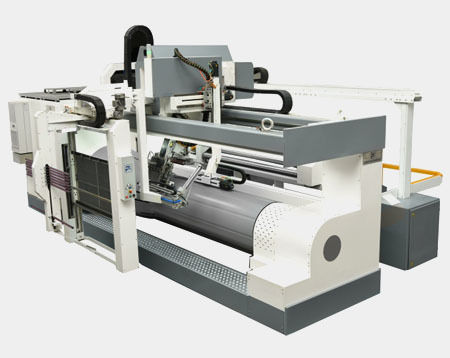

Computer and laser-controlled band-build up - real-time measurement from the first to the last section with central yarn tension control for perfect weaving beams

Vast experience in automatic leasing and band changeover - Karl Mayer has over 150 automatic sectional warpers in the market

DNC KAMCOS SYSTEM - Operator Interface IPC /Touch screen 12.1" Ethernet interface for networking and connection for the relevant data acquisition and Tele-service

Raw Material:

Cotton synthetics wool and their blends

Key Benefits:

NOM brings a new dimension to the sectional warping of samples and short warps whilst guaranteeing efficient production combined with the highest warp quality

Laser control band build-up measuring provides identical band circumference and section carrier trolley feed without stops for correction

The optimised yarn use and new part-creel mode offer shorter setting-up times compared with conventional warping machines.

Clients can avail this Sectional Warper - NOM at industry leading prices from us.

Company Details

Business Type

Exporter, Manufacturer, Supplier

Working Days

Monday To Sunday

GST NO

07AADCA6166D1ZW

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 07AADCA6166D1ZW

New Delhi, Delhi

Sales Manager

Mr. Vikas Sharma

Address

Office No- A-1/172 Ground Floor Main Najafgarh Road Near Narayana Institute Janakpuri New Delhi Delhi 110058 India

Report incorrect details